Imagine you have to give a birthday gift to your best friend: a large mug with a photo of your friend printed on it. This task will be furnished by the“Sublimation Printer” also known as a “Dye-Sublimation Printer” which performs such types of prints. It uses heat and pressure to print a desired image on hard materials like glass shields, wooden items, polyester fabric, mugs, etc. You might have seen such printers in printing presses, gift shops, and garment shops.

Sublimation Printing

A sublimation machine can be created from a normal inkjet technology printer. Just replace the CMYK color ink with the sublimation ink and the normal paper with the sublimation paper.

Users should know that they can convert an inkjet printer into a sublimation machine. But they cannot use it again as a normal color printer. However, printers that use the thermal mechanism for printing purposes cannot turn into a sublimation device, because the thermal technology is not compatible with sublimation ink and paper.

Also, in large-scale production, specifically designed printers for sublimation are available in the market. The price ranges from $200 to $2000, depending upon the printer brand and model. It also differs on the size of the printer you need for a specific purpose.

Sublimation Printer ink

It is a special ink, which works on the principle of transforming directly from solid state to gas, under adequate heat and pressure. Under the heat press colors of sublimation print to convert into gas and infuse onto the polyester fabric. An interesting factor of sublimation ink is that it resists fading, cracking, and peeling. Also, it works best on white or bright surfaces, since white color is not present in most of the sublimation inks. If you intend to unleash your imagination into a useful business, then sublimation ink will resolve your desire.

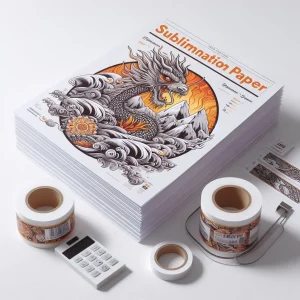

Sublimation Printer paper

This paper is specially designed to absorb the sublimation ink temporarily. Properly load the coated side into the printer. Without burning or scratching this paper can withstand the high temperatures and pressure of a heat press. Based on different sublimation purposes use a suitable sublimation paper. For example, for large-scale production businesses using fast-drying paper is recommended. Keep the paper in a dry place to avoid moisture absorption. Use the proper side of the paper to get print. Make sure to print a mirror image, because the paper flips the other side under heat press.

Sublimation Tape

Sublimation tape is an additional accessory in the sublimation process. It is a specially designed tape to withstand high pressure and heat. It is adhesive on sublimation paper and substrate (T-shirt or mug), yet easily peels off after the heat presses. The purpose of the sublimation tape is to place the sublimation paper on the sublimation item. It helps to prevent the dislocation of sublimation paper during the heat press process. It can bear high temperatures, typically up to 204 Degree Celsius used in sublimation printing without melting, twisting, or leaving remainder. Several types of sublimation tapes are available depending on the required size and adhesive strength. Wider and longer tapes are preferred for large and complex projects, while normal-size tapes are adequate for printing on t-shirts and mugs.

Sublimation Heat Press

In the sublimation printing process, the heat press is an important equipment. It plays a role in transferring the design from sublimation paper onto the sublimation-ready material. Sublimation ink transfers from the sublimation paper to the desired material. Hence, it is a crucial tool in the sublimation process.

Additionally, there are different types of heat press depending upon the purpose of its usage. For example, the clam-shell press helps in sublimation prints of t-shirts and flat and thin surfaces. While the Swing-away press is ideal for large items, the sublimation mug press is specifically designed for mugs and round-shaped objects, and the multi-function press can help in all types of sublimation prints. Make sure to set adequate temperature and pressure before printing to avoid overheating problems. Lastly, always use a sublimation paper in a heat press.

Advantages of Sublimation Printing

- Sublimation prints are non-fading and have vibrant and high-resolution color results.

- Sublimation renders high-quality and everlasting printing.

- Sublimation prints are smooth and washable on fabric.

- Unlike other printers, sublimation printing does not need any cutting or weeding.

Step-by-step procedure for sublimation printer

- Create or edit any images on software like Adobe Photoshop or Illustrator.

- Set the Mirror effect on the image since the image flips during heat press transfer.

- Use a sublimation printing paper to print a mirror image.

- Place the sublimation paper in the desired material to print.

- Use the heat press to apply heat and pressure to transfer the image to a fabric.

- Wait a few minutes to cool down before peeling off the transfer paper.

- The sublimation print is ready for your desired product.

If you encounter any problems while printing, the print test page will resolve the issue.

Note:

Sublimation prints can be applied to a variety of materials including T-shirts, mugs, sportswear, hats, key chains, bags, phone cases, jerseys, home decor fabrics, and more.

Uses of Sublimation Printing

- Non-Fabric materials: Since heat and pressure are required for sublimation printing, it is recommended that prints can be obtained on fiberglass, porcelain, kitchen wares, wooden items, aluminum, and plastic materials.

- Fabric items: T-shirts, tents, bags, flags, and home décor items can be used to get a sublimation print. Unfortunately, Sublimation printing doesn’t work on woolen, cotton, and dark surfaces. Use polyester, nylon, and spandex fabrics for sublimation.

- Canvas: A sublimation print is recommended for high-resolution photographs and canvas art.

- Advertisement banners: Due to the high-resolution quality and non-fading properties of sublimation prints on exposure to sunlight and rain, it is highly recommended for advertisement banners.

Precautions for Sublimation Printer

- One can apply sublimation printing to polyester fabrics.

- You can use at least 60% polyester mix fabric for an ideal print sublimation.

- Sublimation prints are ideal for bright surfaces not on dark fabrics, due to the absence of white color in sublimation ink.

- If white color is essential for a large-scale production, then Diret to Garments “DTG printer” would be the best choice which also works on cotton and woolen fabrics.

- After refilling the sublimation ink, take the Print Test Page to ensure the ink quality.

- Also, you can contact us for any query concerning the sublimation printer.

Sublimation Shirts

It is the best choice for printing desired images on polyester shirts (T-shirts). Customize your shirt design using any application like “Adobe Photoshop” or “illustrator”. Set high-quality resolution, mirror effect, and CMYK color mode. Use sublimation ink and print the image on sublimation paper. Heat press will transfer the image from the sublimation paper onto the polyester shirt. The sublimation print is washable and doesn’t fade away upon sun exposure.

Conclusion

Conclusively, you must be aware that sublimation printing has some limitations. Firstly, it works with a complementary heat and pressure mechanism so don’t use materials that don’t bear any heat or pressure. Secondly, the ink in the transfer paper converts into gas while sticking onto a surface, so woolen and cotton fabrics soak the colors of the ink beyond the need and a blurry print appears. Lastly, sublimation ink doesn’t possess a white color, so printing on a dark surface material will not provide the desired results. Hence, use a “sublimation ready” item for a sublimation print.

Frequently Asked Questions (FAQs)

A sublimation printer puts digital images into a hard reality. Sublimation ink and paper under heat converts the ink into gas, while external pressure instills it on mugs, fabrics, and other well-matched surfaces. As a result, a Vibrant, high-quality, and long-lasting design sublimation print appears on the desired material.

You need to ensure the size and brand of your choice, to further delve into specific models. Among the best printers in demand, Epson sublimation printers stand at the top, while Sawgrass sublimation printers are also in huge demand. Additionally, you can consider affordable sublimation printers like Brother Sublimation printers and Mimaki sublimation printers.

Properly load the sublimation paper. Print the desired image on the sublimation paper and place it on the desired item to get a print. The heat head will provide adequate heat and pressure for a short while. Now, just like magic, the sublimation item will be ready.

You may convert a regular inkjet printer into a sublimation tool for small-scale sublimation manufacturing. However, we recommend using a specially designed printer for large-scale production.

Make sure you have an inkjet printer, not a thermal printer. Now, replace the normal ink from the inkjet printer with the sublimation ink, and properly load papers in the printer. Take a print test page to analyze the proper working of your printer, if it is ok. Just get the print of a selected image. The printer will work as your sublimation device.

There can be several reasons for printing lines on sublimation prints. Firstly, low-quality image selections can cause lines. Secondly, low sublimation ink levels can show gaps as printing lines. Thirdly, blocked nozzles can cause problems with printing lines. Lastly, an uneven heat, pressure, or dislocation of sublimation paper results in printing lines. To diagnose the problem you can use the Print Test Page.

If you are a beginner with a sublimation printer watch a YouTube video by “Clicking Here“.